Mastering CNC Machining: A Guide to Choosing the Best CNC Machine Suppliers

CNC machining is a revolutionary technology that has transformed the metal fabrication industry. As the demand for precision and efficiency grows, understanding how to choose the right cnc machine suppliers becomes paramount for businesses aiming to stay competitive in this dynamic market.

The Importance of Choosing the Right CNC Machine Suppliers

In today's industrial landscape, the machinery you utilize can significantly impact your productivity, quality, and profitability. Selecting reputable cnc machine suppliers is vital for several reasons:

- Quality Assurance: Reliable suppliers ensure that their machines meet stringent quality standards, which translates to better product outcomes.

- Technological Advancements: Trusted suppliers continually update their offerings to reflect the latest technologies, ensuring you are equipped with cutting-edge tools.

- Customer Support: Excellent customer service and support can help resolve issues quickly, minimizing downtime and maximizing efficiency.

- Cost-Effectiveness: Investing in high-quality machines from reputable suppliers can save you money in the long run due to fewer repairs and higher output.

A Deep Dive into CNC Machines

CNC (Computer Numerical Control) machines are sophisticated tools that automate and control machine processes. These machines can perform various operations, including milling, turning, drilling, and more. It is essential to understand the types of CNC machines available when searching for the right cnc machine suppliers.

Types of CNC Machines

- CNC Milling Machines: These are used for producing intricate shapes by removing material from a solid block.

- CNC Lathes: Ideal for creating cylindrical parts, CNC lathes streamline the turning process with remarkable accuracy.

- CNC Routers: Typically used for cutting softer materials like wood, composites, and plastics.

- CNC Plasma Cutters: Utilized for high-speed cutting of metal sheets through Plasma technology.

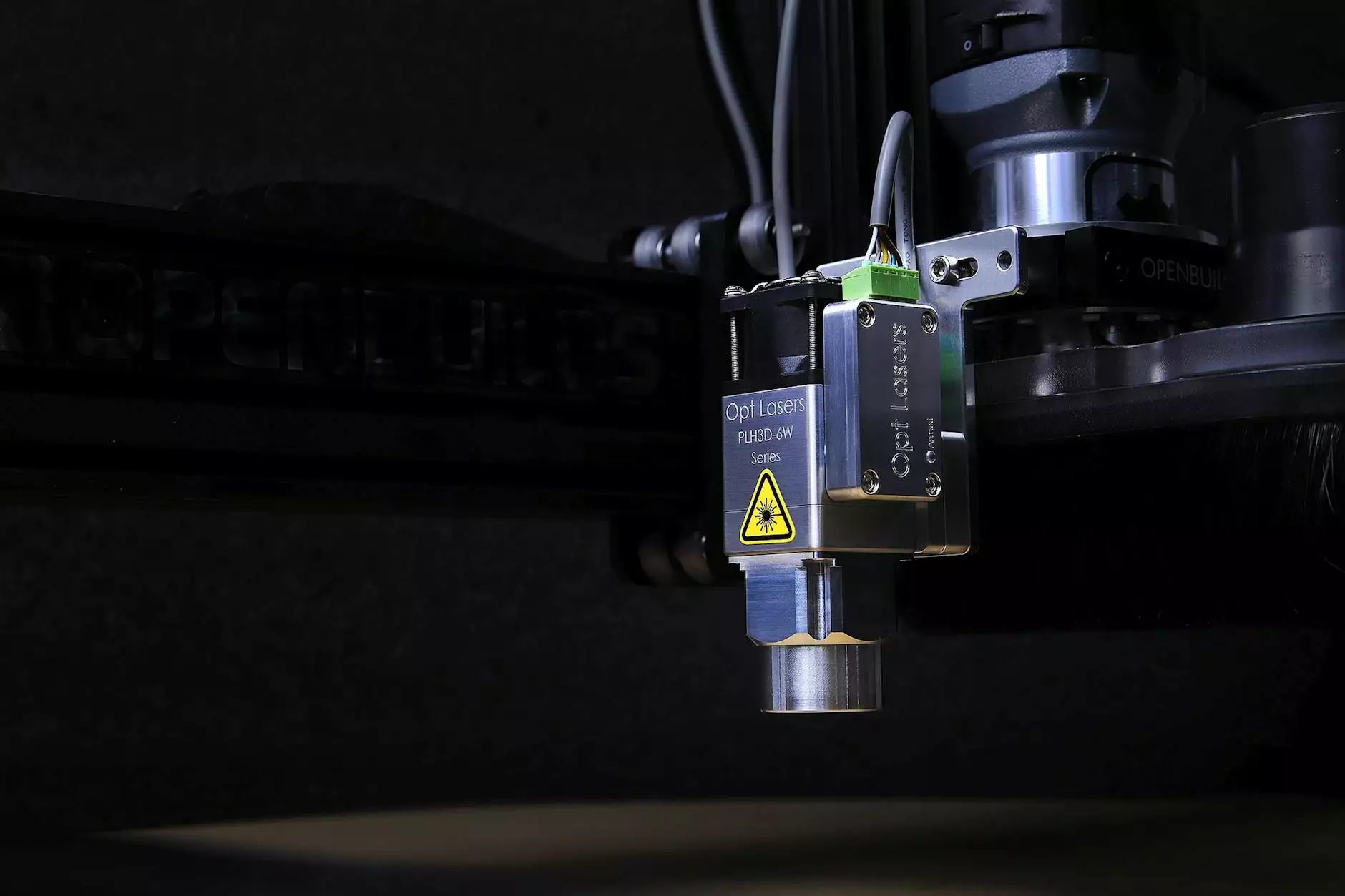

- CNC Laser Cutters: Known for their precision, they are widely used for cutting metal and non-metal materials.

Key Factors to Consider When Choosing CNC Machine Suppliers

When seeking cnc machine suppliers, several crucial factors should guide your decision-making process:

1. Supplier Reputation

Research the suppliers' reputation within the industry. Online reviews, testimonials, and industry recognition can provide insight into their reliability. A strong reputation often correlates with superior service and product quality.

2. Product Range

Choose suppliers that offer a broad range of CNC machines. A diverse product portfolio signifies the supplier's expertise and ability to meet various manufacturing needs. It also allows for easy upgrades and replacements as technology advances.

3. Technology and Innovations

Assess whether the supplier offers state-of-the-art technologies. Suppliers that embrace innovation are more likely to provide tools that enhance efficiency and productivity, which is essential in the competitive manufacturing sector.

4. Customization Options

Consider suppliers that offer customized solutions. Different businesses have diverse machining needs; thus, having suppliers that can tailor their products to fit specific requirements can be beneficial.

5. After-Sales Support

Robust after-sales support is essential for ongoing maintenance and troubleshooting. Suppliers that offer comprehensive warranties and readily available technical assistance can help mitigate risks associated with machine failure.

Building Partnerships: The Role of CNC Machine Suppliers in Your Business Growth

Establishing a solid relationship with trusted cnc machine suppliers is not just about purchasing machinery; it’s about building a partnership that fosters growth and innovation. Here’s how such partnerships can contribute to your business:

- Innovation Collaboration: Suppliers can work alongside your engineering teams to develop new processes or customized solutions that enhance operational efficiency.

- Training Programs: Many reputable suppliers offer training for your staff on new machines, ensuring seamless integration and operation.

- Access to Industry Insights: Established suppliers often have a wealth of industry knowledge that can help you navigate market trends and challenges.

- Volume Discounts: Long-term partnerships can also lead to better pricing structures, potentially lowering operational costs.

Top CNC Machine Suppliers in the Industry

While there are many suppliers in the market, here are some of the industry's top contenders known for their exceptional products and service:

1. Haas Automation

Known for their precision and reliability, Haas Automation is a leading CNC machine supplier, offering a wide range of milling and turning machines.

2. Mazak

Mazak specializes in advanced manufacturing solutions and is famed for its innovative CNC technologies.

3. DMG MORI

Offering a blend of traditional and digital machine tools, DMG MORI stands out for its exceptional build quality and customer support.

4. Fanuc

Fanuc is a renowned name in automation and CNC machine tooling, providing cutting-edge robotics and CNC software solutions.

5. Okuma

Okuma machines are known for their advanced control systems and unparalleled precision, catering to various industries.

Embracing the Future of CNC Machining

As businesses look toward the future, embracing new technologies in CNC machining can yield significant advantages. Automation, Artificial Intelligence (AI), and Internet of Things (IoT) integration are shaping the future of manufacturing:

1. Automation Trends

Automation in CNC machining increases productivity and reduces human error. Suppliers that incorporate automation technology can provide users with a distinct competitive edge.

2. AI in Manufacturing

AI-driven CNC machines can optimize production processes by analyzing data and adjusting operations in real-time, leading to increased efficiency and lower operational costs.

3. IoT Connectivity

IoT-enabled CNC machines allow for remote monitoring and control, enabling faster responses to production issues and maintenance needs.

Conclusion: Making Informed Decisions on CNC Machine Suppliers

Choosing the right cnc machine suppliers is a crucial aspect of optimizing your metal fabrication processes. By considering supplier reputation, product range, after-sales support, and technological innovations, you can make informed decisions that benefit your business. As technology continues to evolve, staying updated on industry developments will ensure that your enterprise thrives in the competitive landscape.

At Deep Mould, we understand the challenges faced by manufacturers and strive to offer tailored solutions that enhance productivity and precision. Investing time in selecting the right suppliers can pave the way for lasting partnerships that foster growth and innovation. Start your journey towards enhanced manufacturing excellence today!