CNC Turned Components Made in China: The Ultimate Choice for Quality and Precision

The manufacturing landscape has evolved dramatically over the years, and one of the sectors that have seen significant advancements is the production of CNC turned components made in China. Known for their unparalleled precision and cost-effectiveness, these components are essential in various industries ranging from automotive to aerospace. In this extensive article, we will dive deep into the world of CNC turned components, exploring their advantages, manufacturing processes, applications, and why they are a wise choice for businesses around the globe.

Understanding CNC Turning

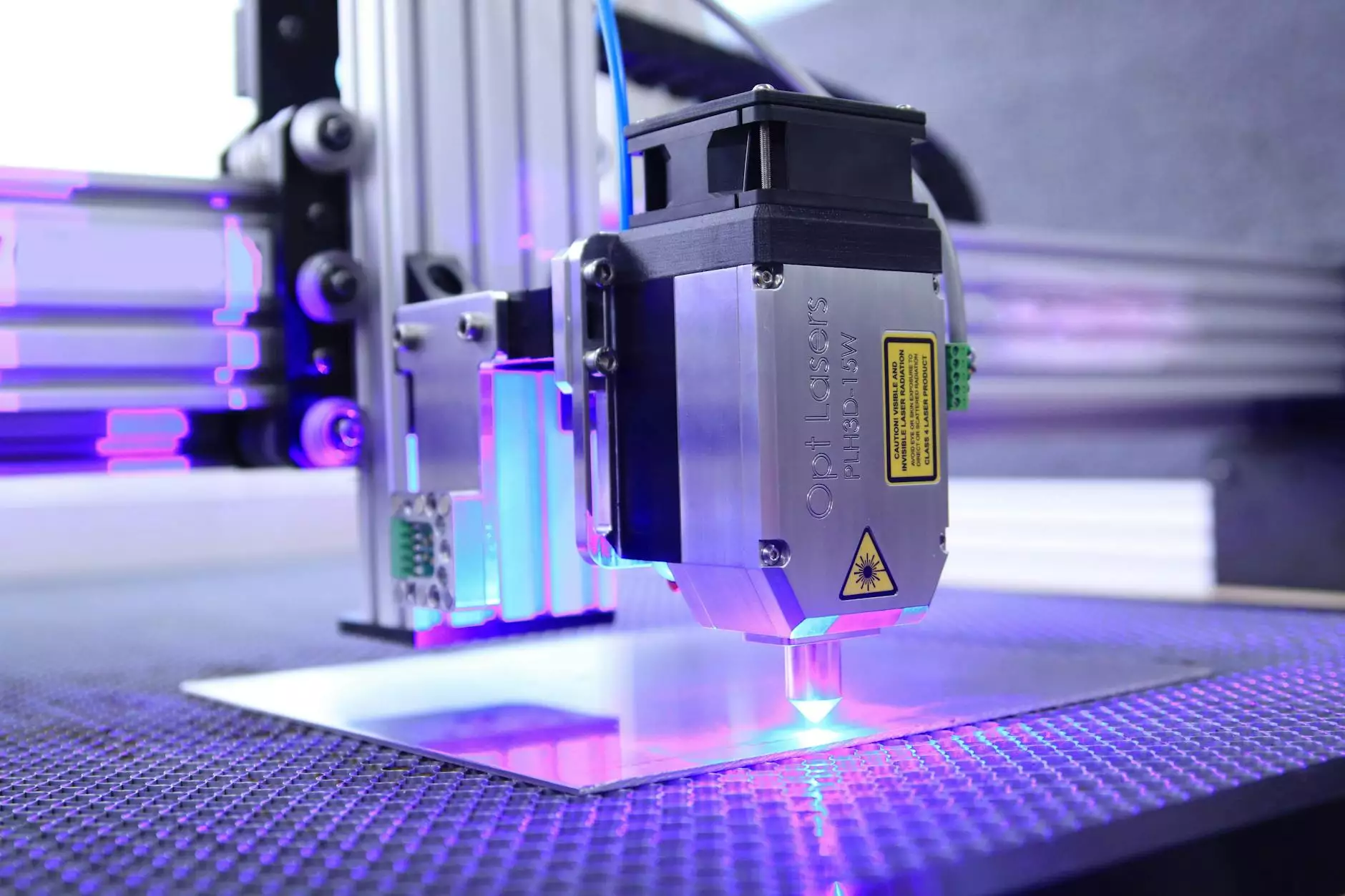

CNC (Computer Numerical Control) turning is a precision machining process that uses computer-controlled lathes to shape materials into desired specifications. This method allows for high precision and consistent quality, making it a popular choice for manufacturers seeking to produce high volumes of components.

The Process of CNC Turning

The CNC turning process involves several key steps to transform raw materials into finished components:

- Designing the Component: Skilled engineers create a detailed CAD (Computer-Aided Design) model of the component. This model serves as the blueprint for the CNC machine.

- Material Selection: Typically, metals such as aluminum, brass, and stainless steel are chosen for their durability and workability.

- Loading the Raw Material: The selected material is securely mounted on the CNC lathe.

- CNC Program Generation: The CAD file is converted into a CNC program that controls the machine's movements with pinpoint accuracy.

- Machining: The CNC machine begins to cut, drill, or shape the material according to the specifications laid out in the design.

- Quality Control: Finished components undergo rigorous testing to ensure they meet quality standards and tolerances.

Why Choose CNC Turned Components Made in China?

The decision to source CNC turned components from China can be driven by several compelling factors:

1. Cost-Effectiveness

China’s advanced manufacturing infrastructure and vast labor market contribute to significantly lower production costs. Partnering with manufacturers in China allows companies to save on material and labor expenses while maintaining high-quality standards.

2. High Precision and Quality Control

Chinese manufacturers often utilize cutting-edge technology and adhere to stringent quality control processes. This focus on precision guarantees that CNC turned components made in China meet international standards and specifications.

3. Rapid Turnaround Times

China's efficient supply chain and manufacturing capabilities enable faster turnaround times. This is crucial for businesses that require large quantities of components within tight deadlines.

4. Diverse Material Availability

Chinese suppliers offer a wide variety of materials suitable for CNC turning, including metals, plastics, and composites. This diversity allows companies to choose the materials best suited for their specific applications.

5. Customized Solutions

Manufacturers are willing to create customized solutions tailored to client specifications. Whether it’s unique sizes, shapes, or additional features, Chinese manufacturers can cater to diverse needs.

Applications of CNC Turned Components

There is a vast array of applications for CNC turned components made in China across numerous industries, including:

1. Automotive Industry

CNC turned components are integral to the automotive industry, from engine parts to transmission systems. Precision is critical in these applications, ensuring the longevity and efficiency of vehicles.

2. Aerospace Sector

The aerospace industry demands components that can withstand extreme conditions. CNC turned parts are used in various aerospace applications where safety and reliability are paramount.

3. Medical Devices

In the medical field, precision engineering is essential. CNC turned components are widely used in medical devices such as surgical instruments and implants, where accuracy can save lives.

4. Electronics

With the rise of technology, CNC turned components are utilized in the electronics industry for parts such as housings, connectors, and circuit board supports, requiring tight tolerances and consistent quality.

The Future of CNC Turning in China

The future of CNC turning in China looks promising as advancements in technology continue to emerge. Innovations in automation, artificial intelligence, and machine learning are set to enhance the capabilities of CNC machines, allowing for even greater precision and efficiency in the production of CNC turned components.

Investments in Technology

Chinese manufacturers are increasingly investing in advanced technologies such as:

- Robotics: Automating processes to improve efficiency and reduce human error.

- IoT Integration: Incorporating Internet of Things (IoT) technology for real-time monitoring and data analysis.

- Advanced Materials: Exploring newer materials that offer superior performance in various applications.

Sustainability Practices

As global awareness of environmental issues rises, manufacturers in China are also adopting sustainable practices. This includes using eco-friendly materials, reducing waste during production, and enhancing energy efficiency in manufacturing processes.

Collaborating with Deep Mould for CNC Turned Components

At Deep Mould, we pride ourselves on our expertise in creating high-quality CNC turned components made in China. With years of experience in the industry, we understand the specific needs of our clients and can offer tailored solutions that meet their requirements.

Our Commitment to Quality

We follow strict quality control procedures at every stage of the manufacturing process. Our skilled workforce and advanced machinery ensure that every component we produce meets the highest standards of precision and reliability.

Customer-Centered Approach

At Deep Mould, we believe that the customer is at the heart of our operations. Our collaborative approach means we work closely with our clients to understand their needs and provide support throughout the entire project cycle.

Conclusion

In conclusion, sourcing CNC turned components made in China presents numerous benefits, including cost savings, high precision, and a wide range of applications. With the ongoing advancements in technology and a commitment to quality, Chinese manufacturers are poised to remain integral players in the global manufacturing landscape.

Choosing Deep Mould means partnering with a leading provider of CNC turned components that emphasizes quality, innovation, and customer satisfaction. Explore our offerings, and let us help you meet your manufacturing needs today!